-

Posts

381 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Store

Gallery

Downloads

Calendar

C-130 Hercules News

Posts posted by munirabbasi

-

-

Just now, munirabbasi said:

Hello Herks Hydro Expertise!

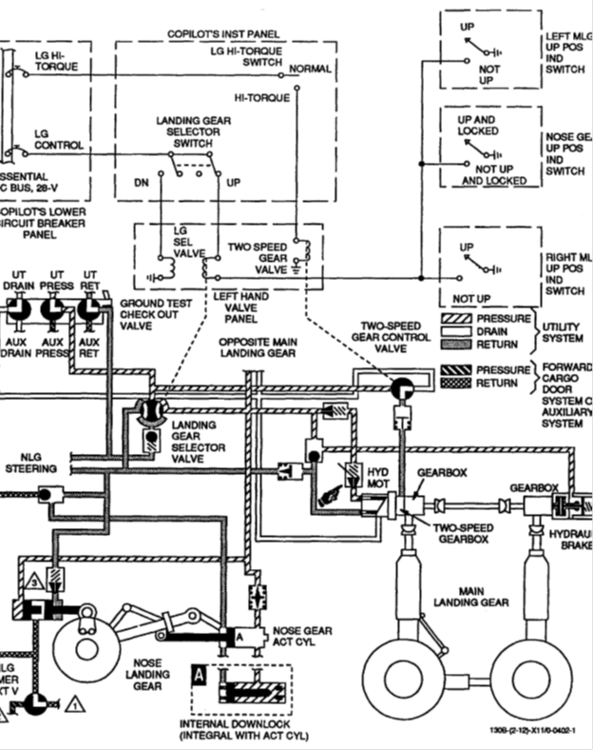

Retraction cycle Timing of Right landing ( B model aircraft) is exceeded from prescribe given time sec ie ,38 seconds with UT hydraulic system but when retracting the landing gear with AUX hydraulic system on ground timing is with in limit ie 17 second . We have replaced right side of landing gear, the flow regulator, controllable restrictor valve, one way restrictor, hydraulic motor ,gear box,landing brake lock and HI.Torque two speed valve but defect was repeated again and again in every sortie. any expert opinion

Best Regards

Munir Abbasi

Home Hercules Pakistan

-

Hello Herks Hydro Expertise!

Retraction cycle Timing of Right landing ( B model aircraft) is exceeded from prescribe given time sec ie ,38 seconds with UT hydraulic system but when retracting the landing gear with AUX hydraulic system on ground timing is with in limit ie 17 second . We have replaced right side of landing gear, the flow regulator, controllable restrictor valve, one way restrictor, hydraulic motor ,gear box,landing brake lock and HI.Torque two speed valve but defect was repeated again and again in every sortie. any expert opinion

Best Regards

Munir Abbasi

Home Hercules Pakistan

-

1 hour ago, n1dp said:

Had to think about this for a while. I remember sitting in the Engineer's seat for many hours pondering the design of electrical systems. The simplicity of the three phase overhead fuel panel switch allows for control even if DC busses are lost. Something you would loose if you used DC power to control a power relay.

Sir David I do not agree with you all three phase ESS AC services (PUMPS) are controlled remotely, Except No.2 Fuel Tank pump.

Munir Abbasi

Home of Hercules Pakistan

-

13 hours ago, NATOPS1 said:

The pumps are connected to multiple power sources (and wire routing) so one set of wires accomplishes a simple control input to the pump regardless of power source.

Thanks for response

Best Regards

Munir Abbasi

Home of Hercules Pakistan

-

21 hours ago, NATOPS1 said:

Change your flexible hydraulic line between the reservoir and the Utility Suction Boost Pump(USBP). IF the line collapses to a degree there will be less hyd fluid (gallons per min) available to pump through the USBP out to the EDP. High demand requires hi volume flow and the only place to restrict hyd fluid affecting both USBP and EDP is the flex line between the reservoir and USBP.

Thanks

Best Regards

Munir Abbasi

Home of Hercules Pakistan

-

On 11/30/2020 at 5:05 AM, hehe said:

Filling the accumulator doesn't honestly do much to prevent an air bubble.

It's the removing of the hydraulic line to the accumulator that create the issue

No matter how fast you are in getting it capped, you will induce a large volume of air into the lines.

I was a hydraulic tech on C-130E/H/J for 13 years. When you think you have the system bled enough, do another 10 cycles.

Thanks for brilliant and quick response sir

Munir Abbasi

Home of Hercules Pakistan

-

The suction boost pumps located near the reservoirs are used to provide a positive hydraulic pressure of 70-l 10 PSI to the suction side of each engine driven pump when turned on. This pressure prevents cavitation and helps to “prime” an engine driven pump should air get into the suction line. If the reservoir fluid level is kept within limits and correct maintenance procedures are followed, air will not enter the system. When a hydraulic component is replaced, the cavities of the new unit should be filled with system fluid (MI L-H-5606) just before installation to minimize entrapment of air. This is especially true when replacing engine driven pumps, Always fill the pump case to overflowing through the case drain port. Also, retain as much fluid as possible in disconnected tubing during component changes. Become familiar with all the instructions in your maintenance manuals to avoid extra expense - and work.

Munir Abbasi

Home of Hercules Pakistan

-

1

1

-

-

15 hours ago, Taimoor said:

Copied Munir Sahab.

Kindly See service news VOL,10.No.2

Best Regards

Munir Abbasi

Home Hercules Pakistan

-

7 hours ago, hehe said:

Lots of things are possible.

I mainly said to check the suction boost pump because you said the light came on. Usually engine pumps will just cause low pressure overall and maybe a low pressure light for that engine driven pump but the suction boost pump light coming on says the supply to both engine pumps was low.

It could have been something as simple as an air bubble making its way through the system when the gear operated. Keep an eye out for having to service air side of accumulators often. If the air charge depletes often, it could be depleting into the hydraulic side and creating air pockets in the system.

Were there any hydraulic compnent changes or hydraulic maintenance that happened before this flight?

Have you bench checked the engine driven pumps?

Excellent Sir hehe

Munir Abbasi

Home of Hercules Pakistan

-

On 11/21/2020 at 7:53 PM, munirabbasi said:

Hello World Hercules Fuel & Avionic Expertise!

All 14 fuel tanks electrical pumps are operated by 3 phase power supply , controlled through 3 phase (4 poles) SWs mounted on OH Fuel control & management panel, where others Aircraft, AC pumps are controlled remotely by single wire (single pole) SWs through 3 phase relays. what is reason behind it?

Best Regards

Munir Abbasi

Home of Hercules Pakistan

Hello World Hercules Fuel & Avionic Expertise!

All 14 fuel tanks electrical pumps are operated by 3 phase power supply , controlled through 3 phase (4 poles) SWs mounted on OH Fuel control & management panel, where others pumps like hydraulic ,prop feathering AUX pump , ACS recirculating fan , are controlled remotely by single wire (single pole) SWs through 3 phase relays. what is reason behind it?

Best Regards

Munir Abbasi

Munir Abbasi Home of Hercules Pakistan

Home of Hercules Pakistan

-

20 hours ago, Taimoor said:

On approach for landing, a C130 E Model aircraft lowers landing gears only. Flaps are already down. While Lowering the landing gears, utility pressure drops to 1375 PSI and low pressure EDP light of both Engines and low pressure light of Utility Suction Boost Pump illuminated. As soon as the Landing Gears were extended completely, system pressure came back to Normal with all conditions within limit. To what component can this occurrence be attributed? Can it be the failure of Utility System Accumulator, Suction Boost Pump or EDP? And if we were to attribute this to Accumulator, is it possible for an Accumulator to suck hydraulic pressure from pressure line to fulfill its pre charge pressure once it is used?

Kindly See the VOL,6 -No.3 service news

Munir Abbasi

Home of Hercules Pakistan

-

10 hours ago, hehe said:

Yea the system isnt designed to prevent a skid at 10 knots.

This might be a pilot training issue more than a system issue

Sir hehe bundle of Thanks

Munir Abbasi

Home Hercules Pakistan

-

2 hours ago, hehe said:

The system should technically skid at 10 knots. The transducers dont have enough current until 15 knots to signal to anti-skid control box.

Does it do it above 15 knots? You might be chasing a ghost here

Above 15 knots system working normal nothing was observed pilot

Munir Abbasi

Home Hercules Pakistan

-

6 hours ago, hehe said:

All 4 skidded or just released pressure?

I would change the anti-skid control box. The entire left and right sides are separated other than the box

All 4 skidded.The electronic box of the system was checked with mark II tester at back shop found OK. The Anti-skid control valves of the system were checked at hydro shop found OK. We also checked the wiring of the system as per T.Os IC-130B-2-13 ,1-1A-14 and 1-1-8 found OK. We also consulted the service news VOL,8-1

Best Regards

Munir Abbasi

Home of Hercules Pakistan

-

5 hours ago, hehe said:

Do your books states that anti-skid in inop below 15 knots? I havent messed with a mark 2 in probably 12 years.

Which side is releasing? All brakes? Left or right?

If its only one side, i would swap wheel speed transducers left to right and see if it follows.

No UNSAT indications were observed. (INOPERATIVE & TEST PANEL LIGHTS) All brakes were released simultaneously.

Best Regards

Munir Abbasi

Home Hercules Pakistan

-

Hello Hydro Expertise

On Aircraft MARK II system, at 10 knots of aircraft speed, brake was released it own when it is applied .Before 10 knots system operation was normal. The system was checked as per T.O 1C-130B-2-12 and 1C-130B-2-7 found OK. Sufficient Hydraulic bleeding was carried out. after completion of two mission defect was repeated again. Hydraulic bleeding of in normal Brake system was carried out but defect was repeated same manner. again. Any expert opinion.

Munir Abbasi

Home of Hercules Pakistan

-

Hello Hercules APU & GTC Expertise

When GTC is in starter cranking cycle (<35% RPM) Bleed & off load control valve is remain energized but APU (GTC 85-180L/LE) The valve is remain De-energized through out starting cycle till APU On speed relay is energized and the bleed control SW is mounted on APU control panel ,placed to open position. What is reason behind it.

Munir Abbasi

Home of Hercules Pakistan

-

Excellent Video

Munir Abbasi

Home of hercules Pakistan

-

Hello World Hercules Fuel & Avionic Expertise!

All 14 fuel tanks electrical pumps are operated by 3 phase power supply , controlled through 3 phase (4 poles) SWs mounted on OH Fuel control & management panel, where others Aircraft, AC pumps are controlled remotely by single wire (single pole) SWs through 3 phase relays. what is reason behind it?

Best Regards

Munir Abbasi

Home of Hercules Pakistan

-

8 hours ago, pjvr99 said:

You will need to do a complete overtorque inspection of the QEC kit and truss mounts, and

also complete overtemp inspection and borescope the turbine, IGV and combustion liners

before attempting to start that engine again

Thanks Peter I need your E mail Address.

Best Regards

Munir Abbasi Home of Hercules Pakistan

-

Hello World Power plant expertise of T-56 A-15

Engine parameter cross the limitation TIT 1100 Celsius, Torque 20000 inch pounds fuel flow meter also cross limitation and could not control by throttle movement. Enine was shutdown as per procedure lay down -1

can some body explain what is the reason behind it and can we run the engine to repeat the defect without rectification.

Best Regards

Munir Abbasi

-

19 hours ago, tinyclark said:

Sorry, I have no idea.

Thanks

Best Regards

Munir Abbasi Home Hercules Pakistan

-

5 hours ago, hehe said:

If electricity sequence is A-B-C, I would assume that you would check C phase because it is the last phase of the sequence. If last phase has correct frequency, the other 2 (A-B) should as well.

Just my thought on it. You would have to ask the electrical engineers that designed it to be sure.

My dear brother I agree with you

Thanks

Best Regards

Munir Abbasi home Hercules Pakistan

-

1

1

-

-

5 hours ago, hehe said:

If electricity sequence is A-B-C, I would assume that you would check C phase because it is the last phase of the sequence. If last phase has correct frequency, the other 2 (A-B) should as well.

Just my thought on it. You would have to ask the electrical engineers that designed it to be sure.

Thanks

Best Regards

Munir Abbasi

Right Landing Gear Timing

in C-130 Technical

Posted

Thanks For excellent Response

Best Regards

Munir Abbasi

Home of Hercules Pakistan