Ahmer

-

Posts

88 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Store

Gallery

Downloads

Calendar

C-130 Hercules News

Posts posted by Ahmer

-

-

Hello Experty ,

Nacelle preheat system inoperative in c130 B & E aircraft, plz any body knows about why this system inoperative,any TCTO or SB referance for deactivates this system, plz share

Regards

-

Hello Alam, problem is might be with inner combustion liner casing metallic seal , compressor rear labyrinth seal or tubine front bearing labyrinth seal.

-

1

1

-

-

43 minutes ago, pmostafiz said:

Every time during decending rpm travel 99.5 to 100.5 at all modes ( Mechanical and normal mode even synchrophaser off) with frequency. Fuel flow and tit stable and no fluctuations. Rpm stable at level flight and on ground.

If fluctuation is in all modes,Most probably cause of valve housing.

-

20 hours ago, pmostafiz said:

7b engine: #2 engine rpm fluctuation about 1% during decending and when goes through the weather. NTS gap is OK and plunger looks good.

Any experience about this?

Hello, at that time ur prop is in normal governing mode or in mechanical mode? If fluctuation is in both modes then change v/Housing filter and then valve housing. Most probably cause of valve governor. Regards

-

6 hours ago, pjvr99 said:

ah i missed the empenage bit. there should be no way for that to happen, unless you have

a problem with bleed air regulators. What happens when you turn on a/i with only the

affected engine bleed air open?

C130 E model no regulator bleed valve used in horse collar, these are motor operated bleed valve . When we used no3 psn bleed for anti icing the torque also rise instead of TIT.

-

7 hours ago, pjvr99 said:

This can be easily verified by disconnecting the CIP line to the FCU. Do engine run. If power still

increases with a/i on. Remove and inspect/replace the cone shaped air inlet fitting in the strut

at 3oclock position (looking into engine intake). You're getting anti-icing air into your CIP line

making FCU add fuel.

When disconnected the hose from FCU & anti icing on how to increase the fuel flow in fcu bleed no added or entering in CIP bellows?

-

6 hours ago, pjvr99 said:

This can be easily verified by disconnecting the CIP line to the FCU. Do engine run. If power still

increases with a/i on. Remove and inspect/replace the cone shaped air inlet fitting in the strut

at 3oclock position (looking into engine intake). You're getting anti-icing air into your CIP line

making FCU add fuel.

Its increase when we on wing and ampen anti icing on & duct anti icing switch Off psn ay that time.

-

8 hours ago, Lkuest said:

does this happen with only that single engine bleed air valve open, or are all 4 engine bleed air valves open? Do you have dummy bleed air valves, or bleed air regulator valves?

Not with all four engines only with no 3 psn engine.

-

Hello expertise T56-a-15 engine at abt 900 TIT when we open wing & empen anti icing TIT remains same but torque of respective engine increase, when close the torque decreases. if any body having good information plz share with us. Regards

-

On 5/10/2019 at 6:42 PM, PauloFerreira said:

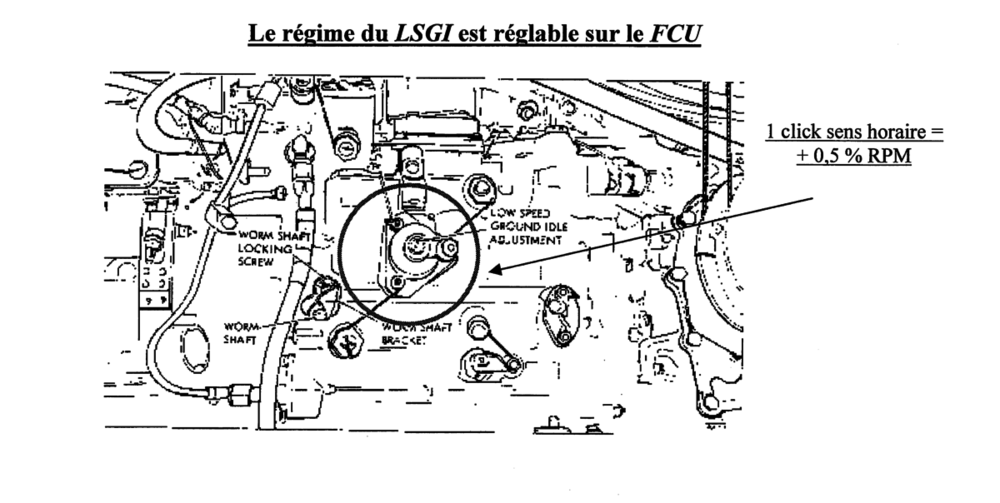

Hi dear paulo, LSGI RPM is 75% & NGI RPM is 95% , what will be ur decision in this situation. How we increase NGI RPM ? Regards

-

Hello expertise, Any body knows about replenishing cycle of Hydraulic MIL-H-83282 on c130 aircraft hydraulic systems. Please informs with Technical order Reference. Tnx

-

Plz installed TD tester, it will identify the component which having problem, if u haven't TD tester and u replaced all components of TD system u also replace LT harness assy, it might be resolve ur problem.

-

9 hours ago, pjvr99 said:

ahmer, this is the problem. we have 380hz/95%, but fsr needs 385hz to engage. fsr is working correctly. engine is also

working correctly but too slow for fsr.

Pj, if u change FSR ,AC cont panel and Generator. U should go to Replace FCU because there is no adjustment of GI & FI rpm if prop angle is with in limit. Regard

-

Hello pj , when u put the engine to normal ground idle, Gen frequency on frequency meter available at GEN switch on OFF position.?

-

If u replaced all thing plz check or replaced auxiliary start relay.

-

Hello, replace APU fuel atomaizer most probably cause of this component.

-

21 hours ago, AMPTestFE said:

But, if you end up operating that engine in NULL, it WILL overtemp, maybe over-torque. Like always, if operating in NULL (or not), you must very carefully watch for this when advancing the throttles.

In Null u must very careful while moving throttle because u havn't overtemprature protection.

-

Bleed valves sticks ,s.s valve malfunction.

-

On 2/1/2019 at 11:17 PM, sharif101 said:

X-over cut back TIT within 15-60°c.

This is correction of TIT 15 to 60 °c not a cut back its miss consecpt.as per 1c-130B-2-4CL-1. But new JG 1c-130H-2-71JG-00-1 having no 15 to 60°c limit its only 800 to 840 limit of cross over TIT no correction mentioned here.

-

2

2

-

-

The dual brake control valve have a metering valve piston is hollow with series of radial at return port end.An over pressure condition in the brake assembly ,caused by thermal expansion ,is automatically relieved by metering valve piston. Regard

-

Yes if NTS system fail prop RPM will be more then power section at that time propeller RPM cross the limit 103.5 . it should be pitch locked and aircraft will yaw opposite direction. If Negative torque increases limit -6000 torque RGB Decoupled from power section. Definitely if outer engine is pitch lock and pilot not confirmed the torque should be more when throttle retarted & aircraft will be yawning opposite direction.we experienced of Pitch lock during NTS system failure during decsanding,Fault is with NTS bracket which not properly actuate NTS system.

-

21 minutes ago, NATOPS1 said:

High speed anything in the Herc is rare BUT in the case of dives there is the ability to have an increase in airflow through the prop which could cause NTS. This could happen with the throttle at flight idle power off or with power on at any setting above flight idle.

As the airflow increase the prop wants to drive the engine as the air becomes the drive force not the engine power.

IF the NTS fails to increase the blade angle drag will be induced; an outboard prop will have more yaw effect than an inboard prop.

Would the prop pitchlock is a dynamic question and is dependent on the situation but in reality pitchlock prevents the prop from decreasing blade angle therefore again in theory the blade should continue to increase blade angle.

ANYONE have the OLD 1960s "PROPORGANDA" illustrated little book that had all the little "engineers" and "mechanics" drawn in? There are some good explanations on this and other prop engine related topics.

NTS system works above flight idle, NTS system work when prop try to rotate engine (during descending,gust load,interruption in TD system,and improper governing) when propeller try to rotate engine (negative torque ) produce this system increase the blade angle when blade angle increase prop RPM decease become in governing range RPM. If ur NTS system fail during descending & NTS system not increasing blade angle through feathering valve and propeller RPM increases obve the pich lock RPM limit ( above 103.5) then propeller should be pitch lock. U can observed pich lock propeller by moving the throttle forward engine RPM follow the throttle movement & torque will be same its indication of pitch lock. REGARDS

-

13 hours ago, munirabbasi said:

I have seen rudder diverter reducer bypass switch mounted center stand flight pedestal but i could not locate on ruder diverter dpanel

Munir Abbasi

It is installed on deverter panel at devert valve on both side utility & booster .regards

-

INOPERATIVE WINDSHIELD ANTI−ICING Operation with inoperative windshield anti−icing is permissible provided. 1. The airplane is not flown in known icing. 2. The maximum speed limit below 10,000 feet is 185 KIAS due to possible bird strikes. Descent from high altitude into warm moist air with an inoperative nesa windshield anti−icing system will cause fogging and possible icing of the windshield. To minimize this, increase cabin air temperature and open the pilot’s and copilot’s windshield defogging valves. It is recommended that a gradual descent be made to allow the windshield, which has been cold−soaked at altitude, to warm with ambient cabin air.

Nacelle preheat system inoperative E Model

in C-130 Technical

Posted

Dear Tiny,

I have all these information, but I want to know when this is inoperative on B & E aircrafts. Intialy which TCTO, Service nees, service later or SB issued for these system to inoperative .tnx

Regards