dash-4A.jpg

Introducing

BROOKS & PERKINS

new A/A32H-4A

CARGO HANDLING SYSTEM

for the C-130 Aircraft

OPERATIONAL READINESS

IN MINUTES INSTEAD OF HOURS . . .

The "Dash 4A” Cargo Handling System for the C-130 incorporates certain improvements shown to be desirable by extensive use of the A/A32H-1A and the A/A32H-4 cargo handling systems— or the "Dash 1A" and "Dash 4" systems— presently being used by the United States Armed Forces and many allied countries.

Simply, the new system attaches directly to the aircraft fuselage structure by the use of standard aircraft bolts. All of the cross members are now removed from the restraint rails and there are no obstructions on the treadways except for the roller conveyors. And, these can be quickly and easily removed and replaced.

As mentioned, the restraint rails of the Dash 4A are attached directly to the aircraft structure, rather than to the cargo tie-down rings with a cross member and conical washer system. It is now a semi-permanent installation and makes available the 5.000 and 10.000 pound tie-down rings for unpalletized cargo.

The outboard roller conveyors are now separate from the restraint rails. This allows both outboard and inboard conveyors to be attached and detached to the aircraft floor using newly designed and installed seat studs. So that the seats can now be lowered and used even with a full plane load of palletized cargo, new seat studs are mounted on the restraint rails.

In addition to these basic changes and improvements, the new Dash 4A System also features an increase in the ramp capacity for the restraint of palletized cargo to 5,000 pounds . . . without exceeding the structural limits of the ramp.

All in all, this new system, compared with the previous and present systems, provides operational readiness . . . through conversion of the plane ' s interior ... in a matter of minutes instead of hours.

The Dash 4A System permits reliable, fast and safe operations in normal cargo handling and in the airdrop of materials. It incorporates restraint and allows for semi-automatic release of the standard airdrop platform and 463- L type cargo handling pallets. The entire weight of the system is under 1,875 lbs.

U.S Coast Guard uses

the new DASH 4A System

to prevent ocean oil spills….

To Prevent ocean oil spills from tankers that have grounded or washed up ashore and threaten to rupture their oil tanks, the Coast Guard has adopted and refined a method of emergency oil transfer using the Air-Pollution Transfer System- or ADAPT System.

The entire ADAPT System is air-dropped from a C-130 transport equipped with the Brooks & Perkins new Dash 4A Cargo Handling System with mating pallets. The ADAPT equipment includes oil transfer pumps, diesel engines, oil transfer hoses and specially developed oil storage containers.

So, no matter what the use or requirement, the Brooks & Perkins Dash 4A Cargo Handling System can do the job… and has, time after time.

For the complete Dash 4A story, write for our illustrated Cargo Handling booklet.

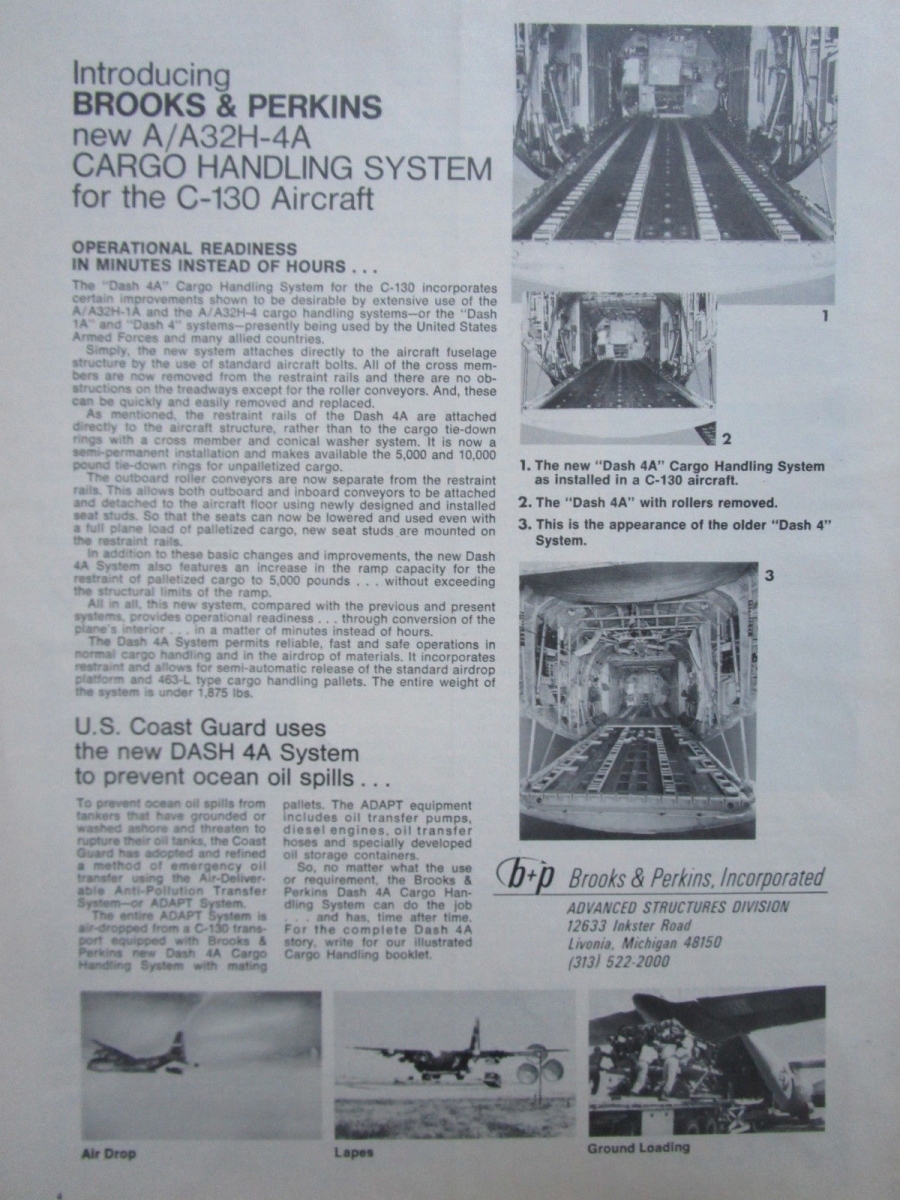

1. The new "Dash 4A" Cargo Handling System as installed in a

C-130 aircraft.

2. The "Dash 4A" with rollers removed.

3. This is the appearance of the older “Dash 4” System

b+p Brooks & Perkins, Incorporated

ADVANCED STRUCTURES DIVISION

12633 Inkster Road

Livonia, Michigan 48150

(313) 522-2000

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.