-

Posts

583 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Store

Gallery

Downloads

Calendar

C-130 Hercules News

Posts posted by pjvr99

-

-

Hey guys, need some thoughts here. One of our birds is throwing a

sh!t-fit, yawing to the left.

Initially, props \'n engines were blamed, but after we changed

the \'offending\' engine/prop combo and no result, the drawing board

was called on. Since then, we have had all the control surfaces off,

replaced the rudder, r/h aileron tab and l/h elevator tab. Also the

aircraft was put through a full symmetry check.

After todays FCF, the pilot told us he had to put in 7° rudder

trim to stay straight after T/O, reducing to 4° for level flight, or do

some serious pedal work. Also lined up torques at 14k and

reduced #3 and #4 to 9400 before yawing stopped.

Aircraft is a standard C130H.

Any ideas will be greatly appreciated .....

-

Seems to be a common problem - people ask for advice, and then don\'t bother to debrief .....

:ohmy: :huh:

:ohmy: :huh: -

donwon wrote:

..... These were great planes in the day.:dry:They still are - their day still has several hours to go!

:) :)

:) :) -

..... bet that messed up the radar picture ..... :ohmy: :ohmy: :ohmy:

-

Ok, that\'s good info. Seems we have 2 possible areas where we can look.....

1. Check bleed sensing lines from starter motor to starter valve for damage/ leaks

2. Check the 1-way bleed-air check valve. The flapper seats and hinges become worn and do not seat properly, or stick in part open positions reducing the amount of air available during starting. I have had 4 or 5 of these in the last 12 months .....

This may be a silly question, but have you checked magnetic plugs? It may be an idea to pull the lower plugs on both the ADH and RGB to heck for debris .....

-

As the stagnation seems intermittent, there may be several different issues involved. Stagnation at 10% may be a failing/failed starter; while at 40%/50% sounds like bleed vlaves closed, although this would need to be confirmed by null/auto start TIT\'s. Also What is the bleed manifold pressure during start? You may have a bad load control valve on the GTC.

-

Thanx Casey, your efforts are really appreciated

-

Taken around 1987, aircraft hit a hawk just after rotation at FADN

-

May have been late 70\'s, I was still at school then. I remember the story making the news at the time, and later at the squadron the subject came up in idle discussion

-

During the early 80\'s, a medical emergency occurred at Marion Island in

the South Indian Ocean. Our B-models don\'t have external tanks, so the

only way to extend the range, to make the relief flight possible, was

to alternate shutting down outboards and inboards ....

The mission was ultimately successful, medical supplies were dropped, and

a life was saved

-

An USAF F16 is escorting a Hercules when the F16 pulls a perfect roll right around the Herc. The F16 pilot then comes over the radio: \"lets see you try that then\"

The Hercules crew ponder for a moment....then shut down number 1 engine. The Herc crew come over the radio: \"lets see you try that then\"!

-

Marhaba from the Magic Kingdom. Welcome to HerkyBirds .....

-

Several bases in South Africa are well out of town, and have large populations of gazzelle and warthog. These end up in engines and undercarriages from time to time. In an attempt to keep these animals away from the runways and taxiways, cheetah are released into the base areas. At least one cheetah has been killed on the runway, and several takeoffs/landings aborted. The overall number of animal incedents has been significantly reduced though

-

Don\'t know the -20, but -30 was 100\" from FS257 marked 257E, 277E, 297E, etc; and 80\" from (I think) FS797 marked 797E, 817E, etc. The origional Flight Stations retained their numbers while the plugs/inserts carry the \"E\" to denote Extension

-

Sounds like a wiring problem. Quickest fix would probably be to replace the inconel fire-wire in the engine and do a test flight.

Question - had the engine been washed recently, i.e. inside the cowls? If the wire is chafed somewhere, water in the open area may be sufficient to momentarily trigger the system.

-

I bet your performance was also around 113%. Not a problem - I had one about 2 years ago. Spent more than a week looking for the problem, until I noticed that the CDP matched the \'Air Start\' pressure guage. I confirmed by adding a third direct reading guage. You have one of the 1-in-1000 engines where the turbine, compressor and associated components match perfectly, coupled to the atmospheric conditions. Just make sure it\'s installed on an INBOARD position, and make a clear entry in the a/c forms. There\'s nothing wrong with it!!

-

I\'m for the cordinator to start, then relay box, then wiring (J3 lead, LH harness, QEC kit harness). Amp would only come into consideration if it is solid state (ABB, Raven, TI, Allison)

-

During the 80\'s, we got the call one of our birds(?) had a birdstrike, and was coming home for repairs. When she flew overhead, it looked like it had been painted with a gloss-coating. After landing we saw it was helo blade-tape over most of the leading edges - during a low-level leg they had surprized a flock of crow-sized birds.

-

duckhunter04 wrote:

We had a simular problem a few years back up here in Kodiak. Above crossover the TD and prop did it\'s job and everything was fine but below crossover and even into reverse we had a FF and TIT flux. Changed fuel control(2), fuel pump and then the TD Valve. Still did it and we needed the plane so we had to change the engine. What finally was the problem was a 3 way elbow/valve assy thats on the bottum of the TD valve and was allowing fuel to flow through it(wrong diection). Of coarse when we did the TD valve change we took the old elbow off and put new orings and installed on new TD valve. What a waste of man hours but I will never forget that again and always put new on new if available!!I remember something similar many moons ago .... still want to know whether the thread-starter resolved his problem

-

DC10FE wrote:

This has been around a while, but a friend sent it to me this morning & I think it needs to be read again.Don R.

YOU MIGHT HAVE BEEN AN AVIATION MECHANIC IF YOU HAVE EVER WORKED AT OR DONE AT LEAST 1 OF THE FOLLOWING..........

Ever drank castor-oil -- and not because of your mother.

Slept on concrete under your jet.

Ever said, \"Oh, yes sir, it’s supposed to look like that.\"

You know what a pointy head is.

You consider \"2380\" finger prints on food an \"acquired taste.\"

Have sucked O2 to cure a hang-over.

You know what JetA1 tastes like.

Used a black grease pencil to fix a worn tire.

You have a better store\'s supply in your coveralls or tool box than store\'s does.

Used a piece of safetywire as a tooth pick.

You refer to a pilot as a \"Control Stick Actuator.\"

You\'ve ever been told to go and get \"a yard of flightline\" or a \"bucket of propwash\" from stores.

Worked a 16 hour shift on a jet and then be told by operations that we aren\'t going to fly it till the next day.

Know that R & R doesn’t always mean remove and replace, but raise and rotate.

You\'ve ever said, \"As long as it\'ll start every other try, you\'ll be fine sir.\"

You\'ve ever considered a traditional Thanksgiving dinner to be a sandwich off of the roach-coach in one hand and a wrench in the other.

You know what a roach-coach is.

And you like the food.

You have ever sat underneath the heat exchangers to get warm.

You\'ve ever towed airplanes around to match the board in operations.

You believe that your \"bird\" has a soul.

You talk to your bird (In your head still counts).

Your spouse refuses to watch any aviation shows with you.

You\'ve ever said, \"That nav light burned out when you turned it on this morning sir.\"

You\'ve ever used a wheel chock as a hammer.

The only thing you know about any city is where the good bars are.

You know more about your co-workers than your own family.

While watching commercials on TV, you look for tail numbers on your birds.

You\'ve ever wished a pilot would just say \"Great bird, thanks.\"

You\'ve ever passed gas in the work truck just to clear it out.

You can\'t figure out why your 2 week advance per-diem is gone after 2 days.

You can\'t get through a trip without finding an ATM.

On a trip, the first place that you go is to the local store on a beer run.

Most of your advance is spent in $1.00 increments in a \"club.\"

You can sleep anywhere -- anytime, but as soon as the engines shut down you are wide awake.

Everyone thinks that your job mainly consists of waving your arms at airplanes.

You have scars on you that aren’t from your spouse or significant other.

You\'ve ever used a seat cushion as a pillow.

Been gouged by the pig tail end of a safety wired cannon plug.

You\'ve ever stood on wheel chocks to keep your feet dry.

You change underwear and t-shirts more times than your coveralls.

Used dikes to trim your finger nails.

Used RTV to fix a stripped screw.

Made tampons out of paper towels for drain hole leaks.

Knocked back a rivet stem that was hanging out of a drain hole.

Wiped leaks down right before a crew show.

The person held with the highest regard is the person that can drink a 6-pack with in a 5 minute period and not puke.

You\'ve ever driven home after working a 36 hour shift, and don’t remember the drive.

You tell your peers that you are getting a divorce and the first thing that they ask is \"selling anything?\"

Everyone you know has some kind of nickname.

I have highlighted more than 5, so I suppose I qualify :laugh:

-

..... any luck clearing this problem ??...

-

This sounds like a problem I had +-2 years ago. Problem is probably not in the prop at all (easily checked by removing the prop and doing a short run). Initially the problem was cured by changing the speed valve, I was venting intermitently, found during a man-on-stand check. The problem returned, becoming progressivly worse.

See if you can attach an air-line and 160psi guage to the bleed valve system DOWNSTREAM of the speed valve. Attach another hose and guage to the CDP fitting. Do a run and compare the pressures from normal to cross-over. There shouldn\'t be more than 10psi difference, and there shouldn\'t be more than 5psi flux on either guage.

Eventually my engine was found to have a bad tower shaft system, causing the flux.

-

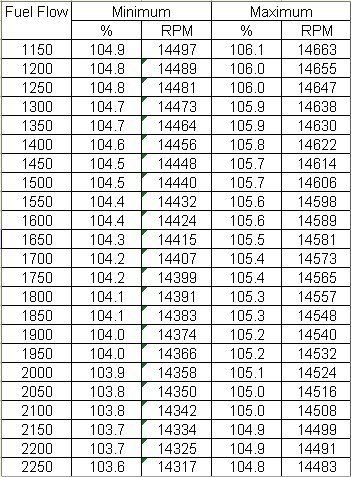

Extracted from the 2J-T56-56: When throttles are at the wall during pitchlock check, check fuel flow, i.e. at 1550pph rpm should be 104.4 to 105.6 (for A15 engine)

-

pjvr99 wrote:

..... bearing in mind when the prop does over-speed, the fuel conrol governor rpm is set according to fuel flow, which mostly is around 104.5% to 105.5%dumb@$$ me: I should have stated that as when the prop does over-speed for fuel governing/pitchlock check ..... etc

:ohmy: :huh:

:ohmy: :huh:

Aircraft misbehaving .....

in C-130 Technical

Posted

NATOPS, as I understand it eventually becomes a roll.