miamiair

-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Gallery

Downloads

Calendar

C-130 Hercules News

Posts posted by miamiair

-

-

To repair a wing leading edge, TO 1C-130A-3 or SMP 583 for a C-130H operated by a European air force?

I 'll post why after a few replies.

Thanks.

-

Ramp/Door seal...

Overhead hatches...

Crew entry door...

-

Need some more help...

Anybody have the list of fasteners needed for the replacement kit? It isn't in the -4.

-

Try Calling WR-ALC Tech Orders: (478)-222-3026

-

Thanks much, gentlemen.

-

I can tell you that, when I was travelling on wing change teams for WR/ALC, we had work packages to follow. After we removed the wings, special two-man teams would come out and do a "planarity check" on the rainbow fitings and then realign the fittings by milling down the nodes that extened too far out in the plane.

Roughly, how long did it take?

-

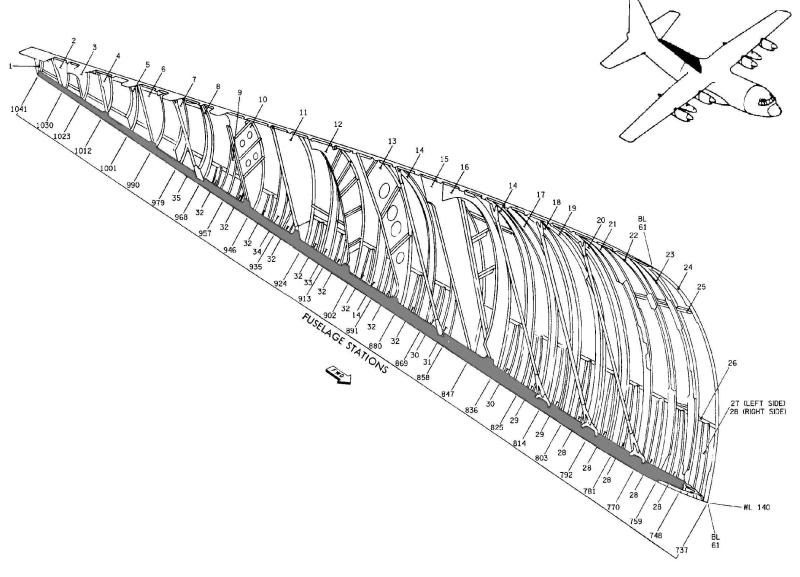

I understand that the work is carried out at the depot level. I have read that the alignment is a must before any work is accomplished. Additionally, the outer wings have to be removed. Other than what you find in the -3, (57-199-XX) is there any other guidance for this task?

-

How extensive a project is it to remove and replace the Rainbow Fittings?

Thanks in advance.

-

Roughly translated:

Hello friends,Recently I have had some problems finding Service Bulletin 382-57-84 ( 82-788 ), in relation to Equivalent Baseline Hours (EBH), I would like to know if someone can send me some information, because I don't know what is the significance.

Thanks for your help.

Regards,

-

That's them, "A," "B," and "C."

-

Contact Tinker Air Force base office in the front of the manual to get permission for you to download or have them send it to your company.

Thats the only thing I can think of. I can send excerpts only from the book or look up part numbers if you like.

The elevator we have is a -9.

We got it without the hinge fittings. We need to do a trial balance check, and that is impossible without the fittings. The poor thing has had the snot beaten out of it by hail.

So what I would need are the P/N's for the hinge fittings to get a set.

-

Try newportaero.com

I tried them already; the 8-10 week lead time makes it a deal breaker.

-

I am in need of a TO for an E-3 Elevator (16C1-7-18-3).

I am a commercial MRO, thus not entitled to go to the USAF to get them. Any ideas?

Thanks in advance.

-

The key is using a protractor to get the correct angle to weigh the reaction.

We just received two that wouldn't balance. The L/H is definitely shot. The MRO used stainless steel for doublers for repairing the web at the tab cut-out. There were numerous rib repairs. Lots of Cheery-Max rivets. Lost cause. This one is getting replaced.

The R/H wouldn't balance either. We found one of the weights had been trimmed and didn't weight what it is supposed to. We replaced that, replaced a whole bunch of Cherries. Needed to add four adjustment weights total. It is now at zero.

But again, the angle has to be on the money, not doing so changes the reaction.

-

Does anyone know where to get the X, Y and Z dimensions for the large bores at the fwd end of the longeron at FS 410.70 where the alignment pin for the Lord Mount. It would be even better if it had the four attach bolt locations in the firewall as well.

There is not a concise figure in TO 1C-130A-3 54-199, unless I am missing something.

Any help would be greatly appreciated.

-

Real simple gents: A man who can't govern his own life should never be entrusted with the government of others.

-

That's what happens when you ride them hard and put them up wet.

-

Has anyone done one of these?

The TO doesn't have any repairs for this area at FS 737. Crack is 7.0-in long(from FS737 to FS 730) in the radius of the "Z".

-

Why not just change the aft section from 737 back? Sounds like it might be easier!!!

Errr, no! Not really feasible.

-

Hello Bonzo,

How long does it usually take you guys...

This bird has both longerons needing replacement along with replacing both 737 terminal fittings.

-

Has anyone ever changed a sloping longeron?

-

Sorry for resurrecting an old post...

The surfaces on the -130 don't have that much repair capability built into them. I've seen this on the ailerons more than any other FC. Every time a repair is riveted on, it is aft of the hinge line, and adds a tail heavy moment to the equation. What we have done to correct this condition is to replace the entire skin panel(s).

Which Structural Repair Manual?

in C-130 Technical

Posted

I'll give you my view, and others can comment and add some light to this...

I think the SMP is for Civilian Hercs and TO's for military Hercs.

Here's an example of a difference, for the same leading edge section, a skin repair requires two rows of rivets under the TO, and four rows under the SMP. Why?