-

Posts

381 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Store

Gallery

Downloads

Calendar

C-130 Hercules News

Posts posted by munirabbasi

-

-

13 minutes ago, Md Abu Sufian said:

The air crew were detailed to carr out a regular cargo msn on route Bunia to goma in C-130B ac ser no 0962.During the takeoff roll,after 60 knots, capt shifted his hand to flt con leaving the nose wh steering as the normal procedure. but at about 80 knots the ac suddenly swung to the left,the capt immediate decided to abort the msn and ac control by applying differential braking with the help of the co-pltand nose wh steering input.

Finaly we suspected that nose steering control valve malfunction during ac speed 80 knots. What might be the reason can anyone inform. Thanks in advance.

Also check LDG torque strut all Strut are same hard or soft and check for Air pressure if soft all strut pressure should be 415 PSI

Munir Abbasi

-

7 minutes ago, Md Abu Sufian said:

The air crew were detailed to carr out a regular cargo msn on route Bunia to goma in C-130B ac ser no 0962.During the takeoff roll,after 60 knots, capt shifted his hand to flt con leaving the nose wh steering as the normal procedure. but at about 80 knots the ac suddenly swung to the left,the capt immediate decided to abort the msn and ac control by applying differential braking with the help of the co-pltand nose wh steering input.

Finaly we suspected that nose steering control valve malfunction during ac speed 80 knots. What might be the reason can anyone inform. Thanks in advance.

Steering control valve lost spring tension It is, mal function of the component, install gauge check pressure on neutral position at point mention on TO (40 psi )as as per TO

regards

Munir abbasi

-

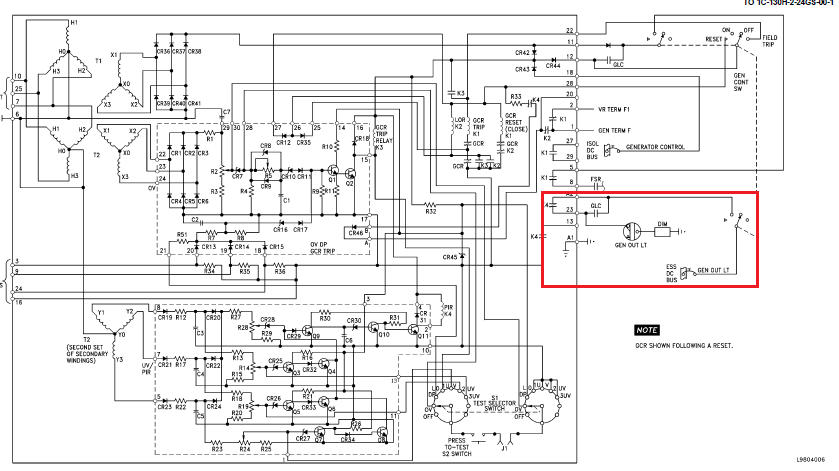

6 hours ago, Cc5 said:

Still dealing with this issue unfortunately. We noticed during takeoff tr3 load skyrockets 15%+ above tr1 inducing a dc bus overload. It will repeatedly fail and recover for 2 seconds a handful of times only during takeoffs.

Check grounding /bonding wire of unit

regards

Munir Abbasi

-

On 8/5/2021 at 1:07 AM, Leakybirds said:

What could be causing a slow moving utility gauge. Pressure reads fine on aux pump, normal and emergency gauge. Just utility gauge shows hesitation. Transmitter and gauge have been replaced. Could it be the util accumulator? Thanks for the help.

Replace transmitter snubber

Regards

Munir Abbasi

-

On 8/4/2021 at 1:07 PM, Leakybirds said:

What could be causing a slow moving utility gauge. Pressure reads fine on aux pump, normal and emergency gauge. Just utility gauge shows hesitation. Transmitter and gauge have been replaced. Could it be the util accumulator? Thanks for the help.

On 8/4/2021 at 1:07 PM, Leakybirds said:What could be causing a slow moving utility gauge. Pressure reads fine on aux pump, normal and emergency gauge. Just utility gauge shows hesitation. Transmitter and gauge have been replaced. Could it be the util accumulator? Thanks for the help.

Check pressure relief valve

regards

munir abbasi

-

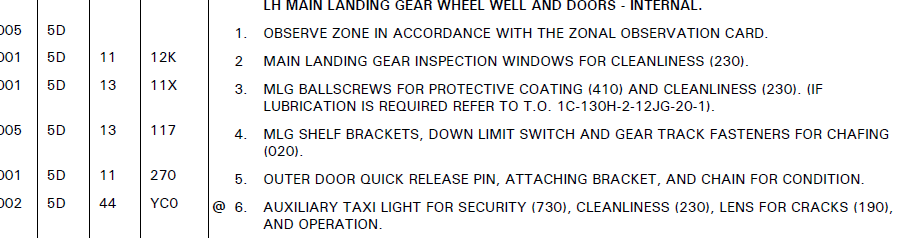

On 6/13/2021 at 9:10 AM, Farhanz said:

Underfloor heat inoperative

- Underfloor heat thermostat plug remove install.

- Underfloor heat switch replacement.

- Swtch toggle replace

- Corrosion treatment temp cont valve

- Thermostat replacement

- Temp cont valve replacement

- Replacement underfloor heat

- Wire No H230A20N repair

- Terminal 15 at TB42L retighten

- Thermostat replacement

- Temp cont valve replacement

- Shut off valve interlock relay replacement.

- Underfloor heat replacement

hello guys, need an opinion to solve this recurring defect. Is there any other step should be done to solve this issue?

EMER DEPRSS & floor heat S/O Valve interlock relay replaced

Best Regards

MUNIR Abbasi

-

7 hours ago, Cc5 said:

Greetings,

We’ve been having an ongoing RTRU issue that only occurs in flight, usually a couple of times during touch and gos/takeoff. TR3 load will drop below 5, kick out a fail for 2-3 seconds then recover and go back to functioning properly. A few things we’ve changed include the TR unit, BIU, as well as the associated diode.

Was curious if anyone has seen a similar issue or has any input on potential culprits. All meter readings weve checked have been good, as it does not fail on ground.

Model of aircraft

Best regards

Munir Abbasi

-

5 hours ago, badr said:

i'm wondering if the park brake is effective without system pressurised.

actually , i parked the aircraft facing a downslope but when we shut down the engines the aircraft started to roll!!! which was freaking!!!! have anyone experienced that before or have any explanation?

UTY/AUX Accumulators Pressure is available for application of brake pressure.

Best Regards

Munir Abbasi

-

45 minutes ago, Leakybirds said:

Thanks for the replies guys. It is a 92 h model. Since my post I have replaced normal selector valve, utility accumulator and ground test valve. Still having issues. Looking into emergency selector valve and shuttle valve During flight of 8 hours its transferring 2 quarts from aux to utility.

Dear It seem to (perhaps) ,your mechanic were doing wrong ways for depleting the aircraft brake pressure without energizing DC buses.

Munir Abbasi

-

On 5/16/2021 at 1:49 AM, smainlion said:

can anyone explain me how to work SPR pressure tester ? .

please I need more information about this apparatus

Your Question not clear

Regards

Munir Abbasi

-

18 hours ago, casey said:

Make sure that the ring for the chain is connected to the side of the pin and not to the button. If the chain is connected to a ring on the button, it can release the pin if the chain is pulled on.

Thanks

Munir Abbasi

-

6 hours ago, larry myers said:

Fourteen years on C-130s, never lost this pin.

As nascarpop posted above, best to insert pin front to back.

Sir You never observe ball of pip pin become U/S or spring lost his tension

Munir Abbasi

-

6 hours ago, nascarpop said:

Pins should always go in from front of aircraft to back of aircraft. Harder to come out that way!

-

1 hour ago, Muhammad Arsalan said:

Question is... What are the possibilities for quick release pin to come off from the hole of stowage rod inside main landing gear along with broken chain during flying mission??

Upper Pip Pin of doors of Main LDGs are secured with safety chains normally but pip pins should be checked by C /chief in every schedule inspection for serviceability ie two balls,with passage of time ball spring loaded are be come U/S one or both. you cannot insert the pip pin during flight /landing/takeoff. It seem to be negligence of crew crew chief

Best Regards

Munir Abbasi

-

7 hours ago, Muhammad Arsalan said:

Is it possible stowage rod upper bracket quick release pin came off from it's hole during flying/takeoff/landing

Question?

Best Regards

Munir Abbasi

-

3 hours ago, Duke said:

Hi folks. Looking to verify something I was told recently about SEA vintage C-130s. Was it possible to lower the ramp/open the cargo doors in flight from the flight deck? If so, would that have been done by one of the pilots or the FE?

Thanks

Yes

Munir Abbasi

-

2 hours ago, Duke said:

Curious if any of you remember the ASC engineering team (me and a young captain) who went around the world giving a briefing on this ditching? We also did a video of the briefing some of you might have seen. I was told the briefing was still being shown well into the late 90s.

Yes

Best Regards

Munir Abbasi

-

2 hours ago, NATOPS1 said:

Sounds like a bad GCP: internal (PIR) or internal TR... Make sure your GCP is the same manufacture as your generator; ALSO make sure the GCP is fully seated in the rack and might want to "adjust it" with a quick hit/rap/ wack to get all the connections to make good contact. SWAP with one of your Eng Gen CGPs to be sure.

Sir When the load of generator was observed satisfactory in every operation checkout of the system it is malfunction of GCP (PIR) wiring.

Best Regards

Munir Abbasi

-

On 4/20/2021 at 10:08 PM, Kaydee said:

I am currently facing a challenge where my APU generator OUT light comes ON, but the frequency and voltage is with allowable limit, also, there is load indication. We have changed the contactor, Voltage regulator and the even the APU regulator but the discrepancy persist. Pls I will appreciate any quick response . Thanks

Kindly check the wiring of auxiliary switching contact of the K-53E and GCP (PIR).

Munir Abbasi

-

I need soft copy of TO 11A18-14

Best regards

Munir abbasi

-

On 4/14/2021 at 5:09 AM, Wheto Joseph Seyon said:

This particular sbag has been disturbing the team for the oast few weeks. What could be the cause, we have replaced the control unit, antenna and also TR unit. Checked every component in the system for serviceability but it still persists.

kindly mention RADAR is installed on your birds .

Best Regard

Munir Abbasi

-

18 hours ago, pgindy said:

Hello everyone,

For the past month or two we've been having an ongoing issue with pressurization on our J model. The problem typically gets recognized when flying at higher altitudes, 19-20k ft, thought recently they've stated they had erratic pressurization at all altitudes. Initially the problem was erratic pressurization throughout flight, resulting in ears popping and discomfort, when at higher altitudes they received a CAB Alt high advisory because cab alt was indicating above 10k ft. We change a part, it flys 1-2 times and the problem comes back. We've changed the outflow vlv, cabin pressure controller, vacuum reg, and servo valve, some things have been changed twice to no avail. Anyone dealt with something similar/have any potential suggestions?

Thanks!

Check the system As per Service News

Best Regards

Munir Abbasi

-

12 hours ago, Sonny said:

Excellent

Munir Abbasi

-

14 hours ago, NATOPS1 said:

You may need to have FLASH available for these animations to work (I think)

GenDisc.exe 286.13 kB · 4 downloads GenDisc TEST.exe 286.61 kB · 2 downloads

Sir Lot of thanks

Munir Abbasi

Home of Hercules Pakistan

APU Start

in C-130 Technical

Posted

ASR malfunction

Munir Abbasi